Mastering Reliability Analysis in ReliaSoft: A Comprehensive Guide

Introduction: Reliability analysis is a critical aspect of engineering and product development, aiming to assess the probability of a system or component functioning without failure over a specified period under given operating conditions. ReliaSoft, developed by Synthesis Engineering Services, is a leading software suite for reliability engineering, offering a comprehensive set of tools and methods for analyzing, modeling, and optimizing the reliability of systems and components. In this comprehensive guide, we will delve into the intricacies of performing reliability analysis in ReliaSoft, covering everything from data collection and modeling techniques to advanced analysis methods and result interpretation.

Section 1: Introduction to Reliability Engineering 1.1 Understanding Reliability: Reliability is defined as the probability that a system, component, or process will perform its intended function under specified conditions for a specified period. Reliability engineering focuses on identifying potential failure modes, assessing their likelihood and consequences, and implementing strategies to improve system reliability and performance.

1.2 Importance of Reliability Analysis: Reliability analysis is crucial for ensuring the safety, performance, and longevity of engineering systems and products across various industries, including aerospace, automotive, electronics, and manufacturing. By quantifying reliability metrics such as failure rates, mean time between failures (MTBF), and probability of failure, engineers can make informed decisions about design improvements, maintenance strategies, and product lifecycle management.

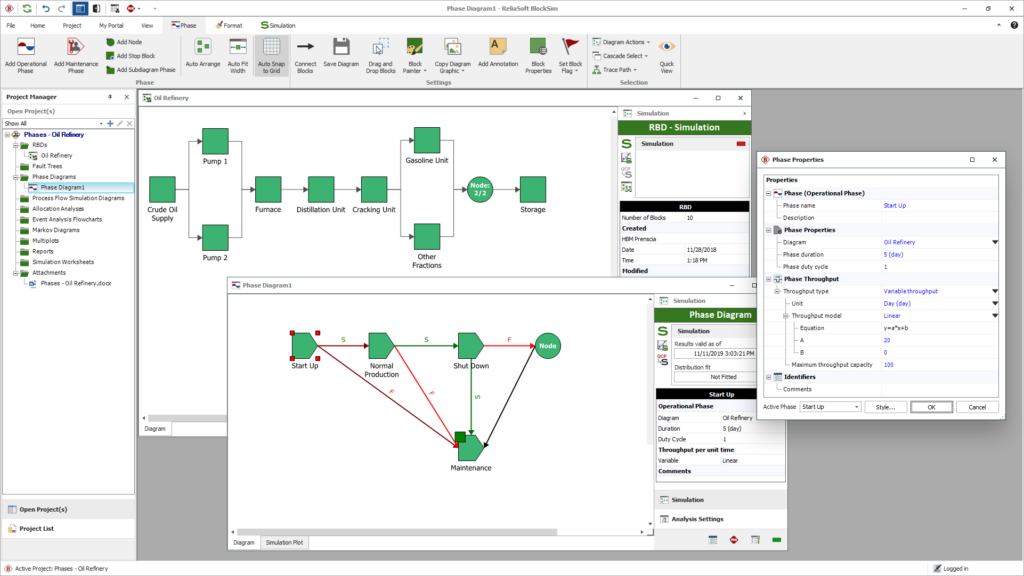

Section 2: Getting Started with ReliaSoft 2.1 Overview of ReliaSoft: ReliaSoft is a comprehensive software suite for reliability engineering, offering a wide range of tools and modules for reliability analysis, prediction, and optimization. ReliaSoft provides an intuitive user interface, powerful data analysis capabilities, and customizable workflows to meet the diverse needs of reliability professionals and organizations.

2.2 Installation and Setup: To begin using ReliaSoft, users need to install the software on their computer systems and set up the necessary license and user preferences. ReliaSoft offers flexible licensing options, including standalone, network, and cloud-based licenses, to accommodate different usage scenarios and organizational requirements.

Section 3: Data Collection and Preparation 3.1 Data Collection Methods: Reliability analysis in ReliaSoft starts with data collection, where engineers gather relevant information about the system or component under study, including failure times, operating conditions, and environmental factors. Data collection methods may include field testing, accelerated life testing, historical data analysis, and expert judgment.

3.2 Data Preprocessing and Cleaning: Once collected, the data undergo preprocessing and cleaning to remove outliers, errors, and inconsistencies that may affect the reliability analysis results. Engineers use statistical techniques such as data filtering, smoothing, and transformation to prepare the data for further analysis in ReliaSoft.

Section 4: Reliability Modeling and Prediction 4.1 Reliability Growth Models: ReliaSoft offers a variety of reliability growth models to predict the future reliability performance of systems and components based on observed failure data. Engineers can choose from models such as the Duane model, Crow-AMSAA model, and NHPP (Non-Homogeneous Poisson Process) model to quantify reliability growth rates, identify failure trends, and forecast future failure behavior.

4.2 Reliability Block Diagrams (RBDs): ReliaSoft allows engineers to create reliability block diagrams (RBDs) to model the reliability and availability of complex systems composed of interconnected components. Engineers can define component reliability parameters, specify system configurations, and analyze the impact of component failures on overall system reliability using RBDs.

Section 5: Advanced Reliability Analysis Methods 5.1 Weibull Analysis: Weibull analysis is a powerful method for modeling and analyzing failure data, particularly in cases where the failure rates vary over time or with operating conditions. ReliaSoft offers advanced Weibull analysis tools for estimating Weibull parameters, fitting Weibull distributions to failure data, and conducting reliability assessments based on Weibull models.

5.2 Accelerated Life Testing (ALT): ReliaSoft supports accelerated life testing (ALT) methods for estimating product reliability and durability under accelerated stress conditions. Engineers can design ALT experiments, analyze test data, and extrapolate reliability estimates to normal operating conditions using ALT models such as Arrhenius, Eyring, and Coffin-Manson models.

Section 6: Reliability Optimization and Improvement 6.1 Reliability Centered Maintenance (RCM): ReliaSoft offers tools for implementing reliability-centered maintenance (RCM) strategies to optimize maintenance schedules and minimize system downtime. Engineers can prioritize maintenance tasks, identify critical components, and develop proactive maintenance plans based on reliability and risk assessments conducted in ReliaSoft.

6.2 Design for Reliability (DFR): ReliaSoft facilitates design for reliability (DFR) initiatives by providing tools for reliability engineering analysis during the product design and development stages. Engineers can perform failure mode and effects analysis (FMEA), reliability allocation, and sensitivity analysis to identify design weaknesses, mitigate potential failure modes, and improve product reliability and robustness.

Section 7: Reliability Demonstration and Verification 7.1 Reliability Testing: ReliaSoft supports reliability testing activities such as life testing, environmental testing, and accelerated stress testing to demonstrate product reliability and compliance with reliability specifications. Engineers can design test plans, monitor test execution, and analyze test data to validate product reliability and performance.

7.2 Reliability Growth Testing (RGT): Reliability growth testing (RGT) is a process for validating and improving product reliability through iterative testing and analysis. ReliaSoft offers tools for planning and executing RGT programs, tracking reliability growth metrics, and assessing the effectiveness of reliability improvement initiatives over time.

Section 8: Real-World Applications and Case Studies 8.1 Automotive Reliability Analysis: In the automotive industry, ReliaSoft is used to analyze and improve the reliability of vehicle systems and components, including engines, transmissions, and electronic control units (ECUs). Engineers use ReliaSoft to conduct reliability predictions, warranty analysis, and root cause analysis to enhance vehicle reliability, safety, and performance.

8.2 Electronics Reliability Assessment: In the electronics industry, ReliaSoft is employed to assess the reliability of electronic components and systems, such as integrated circuits (ICs), printed circuit boards (PCBs), and semiconductor devices. Engineers use ReliaSoft to perform reliability testing, failure analysis, and qualification testing to ensure product reliability and compliance with industry standards.

Section 9: Best Practices and Optimization Strategies 9.1 Data Quality Assurance: To ensure the accuracy and reliability of reliability analysis results, engineers should prioritize data quality assurance activities throughout the data collection and preprocessing stages. Engineers should validate data sources, verify data integrity, and establish data management protocols to maintain data consistency and reliability in ReliaSoft.

9.2 Model Validation and Sensitivity Analysis: Before making reliability-related decisions based on analysis results, engineers should validate reliability models and conduct sensitivity analyses to assess the robustness and accuracy of the models. Engineers should evaluate model assumptions, test model sensitivity to input parameters, and quantify uncertainty to make informed decisions and manage risks effectively.

Section 10: Future Trends and Developments 10.1 Integration with IoT and Big Data Analytics: As the Internet of Things (IoT) and big data analytics technologies continue to evolve, future developments in ReliaSoft may focus on integrating IoT data streams and advanced analytics techniques into reliability analysis workflows. Engineers may leverage IoT sensors, predictive analytics, and machine learning algorithms to collect real-time reliability data, detect anomalies, and predict failure events proactively.

10.2 Digital Twin and Reliability Simulation: Future versions of ReliaSoft may incorporate digital twin technologies and reliability simulation capabilities to create virtual replicas of physical systems and predict their reliability performance under different operating conditions. Engineers may use digital twins to simulate degradation mechanisms, optimize maintenance strategies, and improve product reliability and availability in real-time.

Conclusion: ReliaSoft is a versatile and powerful software suite for reliability engineering, offering a comprehensive set of tools and methods for analyzing, modeling, and optimizing the reliability of systems and components across diverse industries and applications. By mastering the techniques and best practices outlined in this guide, reliability professionals can leverage ReliaSoft’s advanced capabilities to perform reliability analysis with confidence and efficiency, leading to improved product performance, reduced maintenance costs, and enhanced customer satisfaction. With its intuitive user interface, robust analysis algorithms, and extensive data visualization tools, ReliaSoft continues to be a trusted partner for reliability professionals seeking to achieve excellence in reliability engineering and product development.