Mastering HVAC System Modeling and Simulation with TRACE 700: A Comprehensive Guide

Introduction: Modeling and simulating Heating, Ventilation, and Air Conditioning (HVAC) systems are essential tasks in the design and analysis of energy-efficient and comfortable building environments. TRACE 700, developed by Trane Technologies, is a powerful software tool designed to assist engineers, architects, and building designers in modeling and simulating HVAC systems for commercial and industrial buildings. By leveraging TRACE 700’s advanced simulation capabilities, users can optimize HVAC system designs, evaluate energy performance, and comply with building codes and standards. In this comprehensive guide, we will explore the principles, methodologies, and best practices of modeling and simulating HVAC systems in TRACE 700, empowering professionals to design sustainable and energy-efficient building environments.

Section 1: Introduction to HVAC System Modeling and Simulation

1.1 Overview of HVAC Systems: Heating, Ventilation, and Air Conditioning (HVAC) systems are critical components of building infrastructure responsible for maintaining indoor thermal comfort, air quality, and humidity levels. HVAC systems consist of various components, including chillers, boilers, air handlers, fans, coils, ductwork, and control systems, designed to meet building heating, cooling, and ventilation requirements efficiently.

1.2 Importance of HVAC System Simulation: HVAC system simulation enables engineers and designers to analyze the performance, energy consumption, and environmental impact of HVAC systems in building projects. By simulating HVAC systems using advanced software tools like TRACE 700, professionals can optimize system designs, identify energy-saving opportunities, and ensure compliance with regulatory requirements and sustainability goals.

Section 2: Overview of TRACE 700 Software

2.1 Introduction to TRACE 700: TRACE 700 is a comprehensive software solution developed by Trane Technologies for modeling, simulating, and analyzing HVAC systems in commercial and industrial buildings. It offers a range of tools and features for building energy modeling, load calculations, system design, equipment selection, and energy performance analysis, making it a valuable tool for building design and energy management professionals.

2.2 Key Features and Capabilities: Familiarize yourself with the key features and capabilities of TRACE 700, including building geometry input, weather data integration, load calculation methods, HVAC system configuration, energy simulation options, and reporting tools. Learn how TRACE 700’s user-friendly interface and intuitive workflow streamline the process of modeling and simulating complex HVAC systems for diverse building types and applications.

Section 3: Performing HVAC System Modeling in TRACE 700

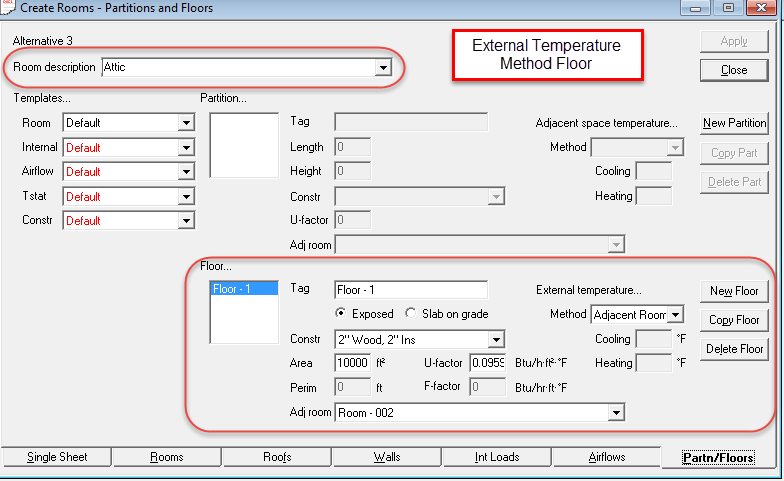

3.1 Building Geometry and Load Inputs: Start by inputting building geometry, orientation, occupancy, and construction details into TRACE 700 to create an accurate building model. Specify internal loads, occupancy schedules, lighting fixtures, and equipment profiles to calculate building heating and cooling loads based on weather data, location, and building usage patterns.

3.2 HVAC System Configuration: Configure HVAC systems in TRACE 700 by selecting appropriate equipment types, capacities, efficiencies, and control strategies to meet building heating, cooling, and ventilation requirements. Design HVAC system layouts, air distribution networks, piping systems, and control sequences using TRACE 700’s system configuration tools and library of equipment models.

3.3 Load Calculation and System Sizing: Perform load calculations and system sizing in TRACE 700 to determine the heating and cooling loads of individual spaces and zones within the building. Use TRACE 700’s load calculation modules, including cooling load calculations, heating load calculations, and ventilation load calculations, to size HVAC equipment, select air distribution components, and optimize system performance.

3.4 Energy Simulation and Performance Analysis: Conduct energy simulations and performance analyses in TRACE 700 to evaluate the energy consumption, operating costs, and environmental impact of HVAC systems under different design scenarios and operating conditions. Analyze energy usage profiles, demand profiles, peak loads, and system efficiencies to identify energy-saving opportunities and optimize system designs for energy efficiency and sustainability.

Section 4: Advanced HVAC System Simulation Techniques

4.1 Dynamic Simulation and Transient Analysis: Perform dynamic simulation and transient analysis in TRACE 700 to simulate HVAC system behavior over time and under varying load conditions. Model system dynamics, control responses, and transient effects such as startup/shutdown sequences, occupancy changes, and weather fluctuations to assess system performance, comfort conditions, and energy consumption accurately.

4.2 System Optimization and Parametric Analysis: Optimize HVAC system designs and conduct parametric analyses in TRACE 700 to explore design alternatives, evaluate performance trade-offs, and identify optimal design solutions. Use TRACE 700’s optimization tools, sensitivity analysis features, and parametric modeling capabilities to adjust design parameters, equipment configurations, and control strategies for maximum energy efficiency and cost-effectiveness.

4.3 Renewable Energy Integration and Sustainability Analysis: Integrate renewable energy sources, energy recovery systems, and sustainable design strategies into HVAC system simulations using TRACE 700. Model solar panels, wind turbines, geothermal heat pumps, and other renewable energy technologies to assess their impact on building energy performance, carbon footprint, and sustainability goals, and optimize system designs accordingly.

Section 5: Best Practices for HVAC System Modeling in TRACE 700

5.1 Data Accuracy and Validation: Ensure data accuracy and model validation in TRACE 700 by using reliable input data, validated building models, and calibrated simulation parameters. Verify simulation results against measured data, benchmarking standards, and industry guidelines to validate model accuracy and reliability for engineering analysis and decision-making.

5.2 Collaboration and Stakeholder Engagement: Foster collaboration and stakeholder engagement in HVAC system modeling projects by involving project stakeholders, building owners, facility managers, and sustainability experts in the simulation process. Communicate simulation results, design recommendations, and performance analyses effectively through presentations, reports, and interactive visualization tools to facilitate consensus-building, decision-making, and project approval.

5.3 Continuous Learning and Professional Development: Stay informed about industry trends, technological advancements, and best practices in HVAC system design and simulation to enhance your skills and expertise with TRACE 700. Participate in training programs, webinars, conferences, and professional development activities to expand your knowledge, network with peers, and stay at the forefront of HVAC engineering and energy management.

Conclusion: Modeling and simulating HVAC systems in TRACE 700 offer engineers, architects, and building designers a powerful toolset for optimizing building energy performance, enhancing occupant comfort, and achieving sustainability goals. By mastering the principles, methodologies, and best practices outlined in this guide, professionals can leverage TRACE 700’s advanced features and capabilities to design energy-efficient, environmentally friendly, and cost-effective HVAC systems for commercial and industrial buildings. With proper training, collaboration, and adherence to industry standards, TRACE 700 empowers professionals to model, simulate, and analyze HVAC systems with confidence and achieve positive outcomes in building design, energy management, and sustainability initiatives.